Drip irrigation: What you need to know

The purpose of this article is to inform you about the basics of drip irrigation so as to determine whether it is the right fit for your project.

Precision irrigation is to deliver the correct amount of food and water to the plant uniformly distributed at the correct time and in the right place considering the smallest differentiable irrigation unit according to the needs of the resources involved.

This definition puts emphasis on the ability to deliver the correct amount of water and nutrients to the plant at the correct time and in the right place.

When we consider the key words in a definition of drip irrigation, it seems like a perfect fit: With drip irrigation water and nutrients are delivered directly to the plant’s root zone, in the right amounts, at the right time.

When applied, managed and maintained correctly, drip irrigation is the most efficient crop irrigation method.

Efficiency has become a keyword in modern farming. There is a lot of pressure on the agricultural industry to use less water and other inputs. With massive competition for water-usage among industries, this pressure is bound to increase. Agriculture must become increasingly purposeful and efficient in the way we use water.

The pressure is on the farmer, but luckily, he can handle the pressure and there are tools to help him to improve his water management. Drip irrigation is one of these tools.

The right system for the job

Having the right tools for the job is a crucial element of efficient irrigation. An informed decision must be made, comparing all suitable types of irrigation to find the best fit for your circumstances. The purpose of this article is to inform you about the basics of drip irrigation, so as to determine whether it is the right fit for your project.

“Water use efficiency must always be the main focus of any irrigation system. To ensure optimal water use efficiency, the choice of irrigation system is extremely important with due consideration of the crop, conditions, and circumstances,” says Jovan Erasmus, Netafim South Africa’s, agronomist for the Northern Region.

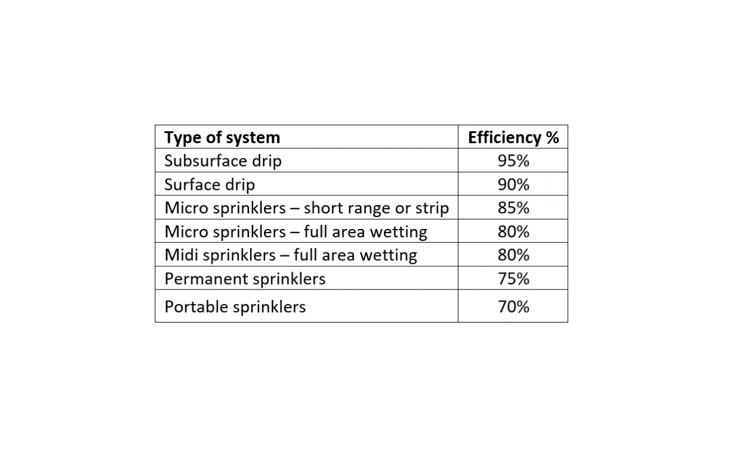

As is clear from Table 1, drip is the most efficient method of water and nutrient application. This high level of efficiency is made possible by a host of advantages. We will elaborate on these advantages later in this article.

Given its high level of efficiency, drip irrigation is often seen as a near-magical irrigation solution. The installation of drip irrigation comes with expectations of skyrocketing yields with minimal water use. These are, of course, not empty expectations, but are dependent on suitable water availability, the selection of the drip irrigation system best suited for your circumstances, correct installation, smart scheduling and faithful maintenance.

With drip irrigation, dripperlines are installed in the field or orchard, either on-surface or subsurface. Drippers are spaced along the dripperline at a certain spacing. This spacing is determined by the requirements of the crop, plant spacing, and the width and depth-wetting ratio determined by the soil’s physical traits. Tailormade spacings are possible to make the system suitable to the conditions. The dripper is selected with a specific flow rate suited to the crop and conditions. Each dripper delivers water and nutrients to the root zone of each plant in the orchard or field.

The concept of drip irrigation was introduced to the global irrigation industry in the 1960s, and ever since massive strides have been made in drip technology. Today, drippers are designed to overcome challenges such sloping fields, challenging water quality, root intrusion and more.

The development of drippers has seen a gradual decrease in the flow rates maintained by drippers, as the industry moves to low-flow drip irrigation. We’ve learned that the traditional application of drip irrigation often means that water delivery is too fast and too deep. Low-flow drip irrigation is increasingly being used and has shown how some crops can really perform. Netafim defines low-flow drip irrigation as irrigation systems in which drippers with delivery rates of 1ℓ/hour and lower are used.

We can now accommodate lower flow rates in drippers without fear of dripper clogging, as Netafim’s low-flow drip technology makes it possible to implement low flow rates, while maintaining clog resistant flow-path dimensions. This is made possible by the patented TurbuNet™ and TurbuNext™ turbulent labyrinths with a much better turbulence coefficient. These labyrinths maintain a unique geometric tooth-shaped structure that increases turbulence, enabling the creation of wider, deeper and shorter passages.

Click here watch a video to learn what sets these labyrinths apart.

“Many South African farmers are convinced that we cannot supply our crops with enough water using low-flow drip irrigation. It is important that we change our way of thinking as an industry, to accommodate new technology and practices. Once we fall behind, we will not be able to catch up again,” warns Jovan. An outcome of low-flow drip technology has been the Centralized Low Flow Drip Fertigation. (Click here to read more about this concept.)

System selection

To make the correct decisions regarding dripper type, flow rate, spacing and other system requirements, we need enough information to base these decisions on. Jovan explains that we need certain knowledge about the plant, soil, water and climatic conditions.

“We must gain knowledge regarding the crop’s water and nutrient requirements, the nature of the root system as well as the sensitivity of the plant-to-root diseases and poor water quality.”

Knowledge about the soil must include soil type, soil chemical and physical composition, relative infiltration rate and the width-to-depth wetting ratio of the soil.

“Knowledge about climate conditions must include rainfall, wind occurrence, temperature and humidity data. All of these factors will determine the crops evapotranspiration (ETo) value, which will determine estimated water requirements.”

Jovan emphasises that this serves as a basic explanation of all the factors that would determine the choice of irrigation system and, after that, decisions regarding dripper and dripperline selection, flow rates, filter selection, scheduling and much more.

Pros and cons

Drip irrigation helps you grow more with less. Jovan explains the main benefit of drip irrigation as its ability to almost eliminate evaporation and run-off, as a very small area is wetted and water is delivered directly to the root zone. “This increases water-use efficiency, helping you grow more with less.”

The benefits of drip irrigation further include:

- Significant water savings.

- A valuable reduction in fertiliser and energy requirements.

- Prevention of fertiliser leaching beyond the root-zone.

- The ability to irrigate larger areas at the same time.

- Significant improvements in crop quality and yield.

- Lower water run-off and fewer topsoil losses.

- Rapid return on investment.

- Noteworthy reduction in the loss of nutrients through leaching.

- Minimised contamination of soil and groundwater.

- Less soil compaction and better root performance.

- Reduction in weeds, and therefore lower herbicide requirement.

- Less dependence on the weather with regard to timing and quantities.

- Lower maintenance and labour requirements

From this list, Jovan highlights the reduction in fertiliser requirements and the prevention of fertiliser leaching. “Drip irrigation allows you to deliver nutrients to the plant through the irrigation system. This is known as fertigation. Dissolved fertiliser is delivered to the plants in a readily available form. It can therefore be easily and immediately taken up by the plant.

“This not only means that fertiliser is used more efficiently, but also that it can be applied more often and in smaller quantities rather than one large application at the start of the season. It will also allow the farmer to adjust the fertiliser application during the season.”

An often forgotten benefit of drip irrigation, says Jovan, is that you do not wet your leaf canopy. “High salt content in the water can, for example, burn leaves. With drip irrigation, the leaves are protected as water is delivered directly to the root zone. This also prevents the spread of bacteria on leafy vegetables, such as spinach and lettuce.”

No system is without possible disadvantages. “Users are often deterred from drip irrigation by the fact that you cannot see the water as it is delivered to the plant. Whether the system is installed subsurface or on-surface, the irrigation activity is near invisible and it is difficult to identify problems in the fields.”

Another possible disadvantage of drip irrigation is its high filter requirement and its sensitivity to poor water quality. This can mostly be mitigated by the correct filter selection, but there are cases where the quality of the available water source will make it challenging to use drip irrigation.

“It is important to have your water source analysed and to include experts, such as Netafim’s agronomists, in the process to determine whether your available water is suitable for drip irrigation and make recommendations about the most suitable system,” says Jovan.

Do it right

Jovan encourages farmers to reject the notion that you have to see the water being delivered to plants and that you need to be able to physically inspect emitters. “Drip irrigation can be trusted and with proper maintenance and the right drip technology clogging risk becomes very low.”

Once you have determined which type of irrigation product will be best for your circumstances, be sure to select products with a proven track record. You cannot afford to risk the financial viability of your investment by not investing in the best possible irrigation equipment.

Remember, the quality of a product depends on both its technical features and the way it is designed and manufactured. The way a dripper, for example, is designed and manufactured is the secret factor that makes the difference between a good quality and poor quality dripper, if all technical aspects are equal. If the dripper flow path is not optimally designed and manufactured, clogging risk, for example, will be higher. Other specifications will have to be adjusted to compensate, which may have other detrimental effects on overall dripper efficiency.

Click here to view Netafim’s dripper selection.

Share your thoughts

Comments

We'd love to hear your thoughts! To enter a comment, type your name and email address.