Turbulence and filtration area – do they really keep a dripper clean?

By Jerry Austen and Seba Schifris, Netafim.

In previous articles, we have looked at the features that keep a dripper clean and concluded that essentially, it comes down to two features:

- K - The turbulence coefficient

- EFA - The effective filtration area

The previouse articles were published in the SABI magazine, read these articles here:

Much has been written about these features. But this is all theory. In practice, do these two features really contribute to keeping a dripper clean?

Let’s recap.

Turbulence coefficient

The total head loss (pressure loss) through a dripper comprises two sources:

- Laminar flow friction loss

- Turbulence

The less turbulence that a dripper can create, the more it will need to resort to laminar flow friction loss to achieve the necessary head loss. However, laminar flow does not contribute to keeping a dripper clean. For that, we need turbulence. Turbulence is measured by the turbulence coefficient (K). The higher the value of K, the better the dripper will be at keeping clean.

The equation for the turbulence coefficient is:

K = 254 * P * (W * D)² / (N * Q²)

- K – Turbulence coefficient

- P – Pressure differential through the labyrinth (m)

- W – Labyrinth width (mm)

- D – Labyrinth depth (mm)

- N - Number of teeth in the labyrinth

- Q – Labyrinth flow rate (ℓ/h)

From this equation it can be seen that the higher the values of W and D (labyrinth width and depth), the higher will be the value of K (turbulence coefficient).

It can further be seen that the lower the value of N, the higher will be the value of K (turbulence coefficient). The lower the value of N, the less the number of teeth. The less the number of teeth, the shorter will be the labyrinth length. Shorter (or less teeth) is better.

Figure1: The labyrinth of a modern dripper

We know that a dripper with a larger labyrinth width and depth will be better than one with a smaller width and depth. We also know that a dripper with a shorter labyrinth will be better than one with a longer labyrinth.

But what happens if one dripper has a large labyrinth width and depth, and another has a short labyrinth? Which one is better? It is impossible to answer this question by just comparing the two drippers. But the turbulence coefficient wraps all relevant features into one measurement. The one with the highest turbulence coefficient is the better dripper.

Effective filtration area

A dripper filter is built-in to a dripper’s inlet. The effective filtration area is the sum of the open gaps through which water flows before entering the dripper.

Figure 2. The filter at the inlet of a modern dripper

Other than by dripline flushing, once a dripper’s filter is contaminated, the dirt cannot be removed. Essentially, the larger the EFA, the longer it will take to get contaminated and the longer it will last.

Dripper quality score

In the SABI Magazine Jun/Jul 2019 issue (3), we considered a system for comparing drippers. A dripper quality score (DQ) is obtained by combining K and EFA with a weighting for each.

DQ = (W1 * EFA) + (W2 * K)

- DQ - Dripper quality score

- EFA – Effective filtration area (mm)

- W1 – Filtration area weight factor

- K – Turbulence coefficient

- W2 – Turbulence coefficient weight factor

W1 and W2 are chosen by the user, and in this case are selected as 1 and 10 respectively.

In practice - clogging tests

To test the ability of K and EFA to keep a dripper clean in practice, Netafim has compared drippers with varying turbulence coefficients and effective filtration areas and subjected them side-by-side to the same dirty water over a fixed period of 21 weeks.

During this period, the grade of filtration was progressively relaxed. In other words, the water got dirtier over time.

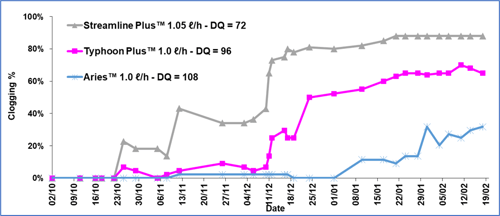

First, let’s look at three models of Netafim non-pressure compensating drippers with the same flow rate, but different labyrinth dimensions and different effective filtration areas.

Table 1. The turbulence coefficients and effective filtration areas of three non-pressure compensating drippers.

|

Model |

Flow rate (ℓ/h) |

Width (mm) |

Depth (mm) |

Number of teeth |

Turbulence coefficient (K) |

Effective filtration area (mm²) |

DQ score |

|

Streamline Plus™ |

1.05 |

0.51 |

0.44 |

13 |

5.9 |

14 |

72 |

|

Typhoon Plus™ |

1.00 |

0.60 |

0.59 |

44 |

7.2 |

24 |

96 |

|

Aries™ |

1.00 |

0.60 |

0.74 |

85 |

5.8 |

49 |

108 |

Chart 1. Dripper clogging over time of three non-pressure compensating drippers.

Chart 1 shows how after the 21 weeks, Streamline Plus™ drippers with the lowest DQ score, the highest percentage of clogged drippers. This was followed by Typhoon Plus™ with a higher DQ score and Aries with the best DQ score had the lowest percentage of clogged drippers.

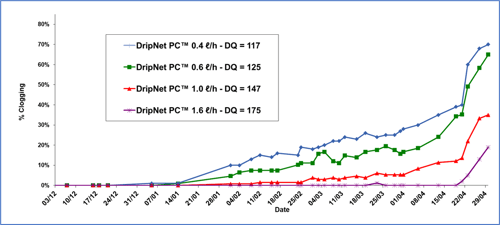

Now let us isolate the dripper turbulence coefficient. We look at K’s influence on clogging without the influence of the effective filtration area. We will use one model of dripper with the same filtration area for all flow rates, with the one exception of one flow rate, 0. 4 ℓ/h*.

*The DripNet™ PC pressure compensating dripper range is manufactured with flow rates from 0.4 ℓ/h up to 3.8 ℓ/h. The turbulence coefficients of four of these flow rates – the more common lower flow rates - have been selected.

When using the same model dripper with the same labyrinth pattern, it is only possible to design a change in flow rate by altering the dimensions of the labyrinth: that is the width, depth, and length (number of teeth). Lower flow rates will require narrower and/or longer labyrinths. It therefore stands to reason then that the same model dripper with a lower flow rate will have a lower turbulence coefficient.

Table 2. The turbulence coefficients of the DripNet™ PC dripper

|

Flow rate (ℓ/h) |

Width (mm) |

Depth (mm) |

Number of teeth |

Turbulence coefficient (K) |

Effective filtration area (mm²) |

DQ score |

|

0.4 |

0.46 |

0.52 |

36 |

8.8 |

29* |

117 |

|

0.6 |

0.52 |

0.60 |

24 |

8.6 |

39 |

125 |

|

1.0 |

0.61 |

0.60 |

11 |

10.8 |

39 |

147 |

|

1.6 |

0.76 |

0.73 |

9 |

13.6 |

39 |

175 |

Chart 2. Dripper clogging over time of the same model dripper with four different flow rates.

As in the first case, the graph confirms that the lower the dripper quality score, the greater the clogging. This even applied to the 0.6 ℓ/h, 1.0 ℓ/h, and 1.6 ℓ/h whose effective filtration areas are all the same. The only influence is the different turbulence coefficients. Even though the 0.4 ℓ/h dripper’s turbulence coefficient is marginally higher than the 0.6 ℓ/h dripper, its smaller EFA effectively brought down its DQ score and thus increased its clogging.

Yes, K, EFA and DQ matters

To answer to the question, in practice, do the two features turbulence coefficient and effective filtration area really contribute to keeping a dripper clean? Based on the results of subjecting different drippers to identical water quality, it would be reasonable to say yes. The higher the turbulence coefficient and the larger the effective filtration area, the higher will be the dripper quality score and the better that dripper will be at keeping clean.

Share your thoughts

Comments

We'd love to hear your thoughts! To enter a comment, type your name and email address.