The Power of Prevention: Protecting the Precision in Irrigation

Let’s talk about the importance of religious maintenance in drip irrigation success. The many advantages of this precision irrigation method quickly diminish when systems are not properly designed, operated, and maintained. Dripper blockages, flow rate inconsistencies and other problems will arise, often silently and cumulatively, leading to significant losses.

Two areas where suboptimality often sets in, and where it can most easily be addressed, are scheduling and maintenance. A lot has recently been written by our experts and many other industry experts around scheduling and understanding the way water moves in soil. This article will focus on the importance of regular maintenance and crucial maintenance activities. The many advantages of precision irrigation quickly diminish when systems are not properly designed, operated, or maintained. Without preventative maintenance issues such as dripper blockages and flow rate inconsistencies can arise, often silently and cumulatively, leading to significant losses.

Based on Team Netafim’s experience in the field, we believe the following three beliefs are core to successful drip irrigation maintenance to ensure drip irrigation system longevity:

- Preventive maintenance trumps reactive maintenance: Proactive actions prevent breakdowns, save cost, increase efficiency, and extend system life.

- System design must enable maintenance: Include features such as lateral flushing capabilities, flush valves, secondary filters, injection points, and vacuum valves from the get-go.

- Continuous water quality management is required: Seasonal water testing is non-negotiable. Regular analysis helps tailor maintenance and treatment plans to current water quality conditions.

The war on clogging

Netafim field teams routinely encounter drip installations where problems such as irregular flow rates or zero delivery occurs. More often than not, they find that maintenance has been neglected or performed incorrectly and that these issues could have been entirely avoided through systematic preventative practices.

Dripper clogging is the clearest example of why preventative maintenance is critical. Once a dripper is clogged, restoring flow is extremely difficult, if not impossible. That’s why the emphasis is on prevention, not correction. Choosing high-quality drippers, adding sufficient filtration and ensuring correct system design is essential, but long-term system health depends on how the irrigation system is maintained.

Dripper clogging can be caused by a myriad of reasons, including mineral precipitation, biological growth, or the presence of physical debris such as sand or silt. Regular flushing of laterals, lateral manifolds, and mainlines prevents build-up, while chemical treatments like acidification, chlorination, or hydrogen peroxide can keep mineral deposits and biofilms under control. Each maintenance action must be adapted to the water source, crop type and the layout of the irrigation system.

A structured maintenance routine

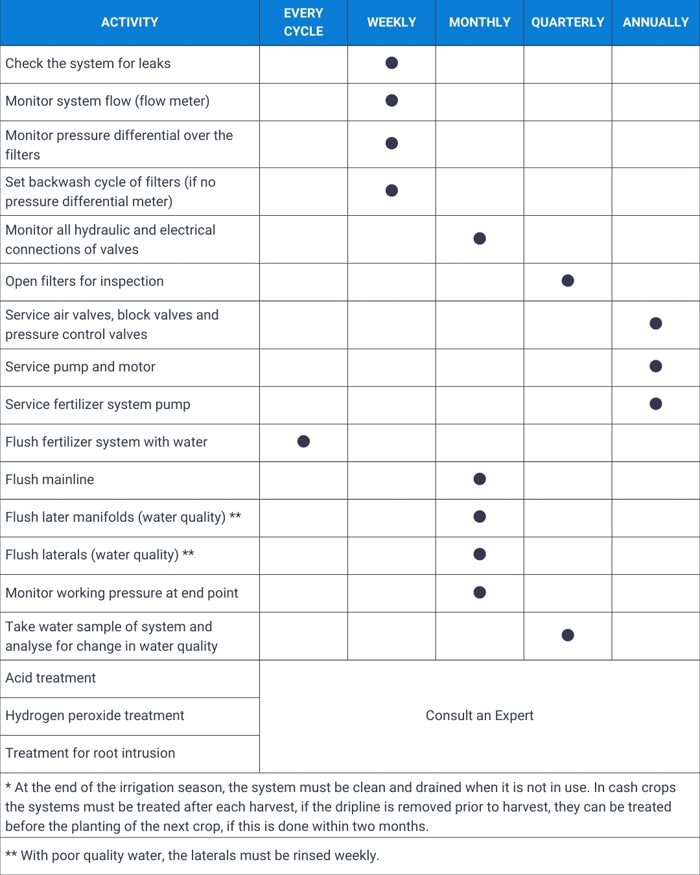

All drip systems consist of several components that require focused attention at different stages throughout the season. A good maintenance schedule is often structured around weekly inspections, maintenance before the irrigation season starts, and maintenance at the end of the irrigation season. Having placed emphasis on the prevention of dripper clogging, it is important to note that proper drip irrigation system maintenance goes far beyond the maintenance of driplines. It starts in the head control room (pumphouse) and enquires important actions all the way to the field. It includes proper filter maintenance, attention to mains and lateral manifolds, pressure checks, valve maintenance and more.

A holistic maintenance plan must be set out and strictly followed. Weekly activities include f lushing driplines, checking pressure differentials across filters, and inspecting for physical damage or leaks. Seasonal maintenance involves chemical treatments, pressure checks, and verifying emitter performance. Be it weekly or seasonal activities, it is important that the entire team is committed to the plan and trained on the necessary actions and their timing.

Preventative precautions

Basic, but critically important precautions must be taken during irrigation system design and operation to prevent dripper clogging and ensure system longevity.

These precautions include:

- Having a system design that enables easy maintenance

- Installing vacuum valves

- Installing flush valves

- Installing chemical injection points

- Doing a water analysis and designing the system accordingly

- Installing and maintaining suitable filtration, both primary and secondary

- Doing regular water quality analysis and maintaining the water source

- Following the correct installation procedures

- Ensure that the mainline and lateral manifolds always stay clean, keep inlets and outlets covered, flush all lines after installation

- Installing a floating suction at the water source to reduce particle intake

- Positioning the dripline correctly according to intended use and conditions

- Protecting the installation from vandalism

- Clearly marking all in-field valves to prevent damage from machinery

- Setting up and following a strict maintenance programme

- Doing proper and regular maintenance training for all relevant staff

- Doing regular visual inspections

- Regularly flushing driplines, lateral manifolds and mainlines

- Turning on the system when necessary to rinse fertilizer-enriched water from the system

- Correcting the pH level of the water to prevent calcium and magnesium precipitation

- Applying practices to enable oxidation of iron and manganese (such as having a settling dam)

- Injecting suitable chemicals to prevent biofilm formation

Keeping an eye on the system

Visual inspection and testing of components is an integral part of preventative maintenance, be it monitoring flow rates, cutting open drippers, checking, inspecting filter discs or checking the pressure differential between the filter inlet and outlets. This ensures that possible problems are identified and corrected before they have a significant impact on the efficiency and longevity of the entire irrigation system. Regular inspections are the heart of preventative maintenance and must not be skipped at any cost.

Important inspection activities can include:

- Monitoring pressure and flow rate at the dripper level

- Monitoring pressure differentials at filter level

- Checking for dripper clogging and emitter uniformity by cutting open selected drippers in addition to monitoring flow rates

- Measuring pH, H2O2, and chlorine residuals when treating water

- Testing and calibrating injectors

- Checking driplines, lateral manifolds and mainlines for physical signs of damage

- Checking all other system components regularly, such as valve operation, status of filter discs etc.

Regular visual and data-driven evaluations can help you detect early signs of system stress - before problems escalate into costly repairs, breakdowns or losses in yield.

Regular Dripline Flushing

A dentist’s passionate preaching about flossing is nothing compared to a drip expert’s gospel on regular dripline flushing. Regular flushing is non-negotiable as it prevents particles from settling in the dripline and dripper. Driplines should be flushed with enough velocity (0.5 m/s) to move debris to the end and out of the line. It is recommended to flush mains, lateral manifolds, and driplines weekly during peak irrigation activity and do technical irrigations after rain events and after fertigation. Turn on the system and allow it to reach operating pressure, then flush the main, lateral manifolds and lastly the driplines. Be sure to only flush a few driplines at a time to ensure effective pressure.

Correct Chemical Treatments

Preventative chemical treatments can be a very powerful tool in drip irrigation system maintenance and many field tests and research are ongoing in this regard. The secret is that these treatments work - when done right. Ensure to collect the necessary information, adhere to all safety measures and consult the necessary experts before doing any treatments.

Treatments can include:

- Acidification: Dissolves mineral build-up from carbonates or phosphates.

- Chlorination: Targets organic matter like bacteria, algae, and slime.

- Hydrogen Peroxide: A robust oxidizer effective against organic residues, and more pH-stable than chlorine.

- Two-stage Treatments: Combining acid and hydrogen peroxide treatments (never simultaneously) offers a powerful solution to severe clogs, especially in systems affected by iron or manganese bacteria.

Protecting Precision

Preventative maintenance isn’t just an option—it’s a necessity. A necessary step to protect the potential of precision-driven yields, and protect the investment made in precision irrigation equipment. Invest the time, build the routine, and train your team. Your orchard, vineyard, or field, and the bottom line, will thank you.

Share your thoughts

Comments

We'd love to hear your thoughts! To enter a comment, type your name and email address.