Select the best thin wall dripline

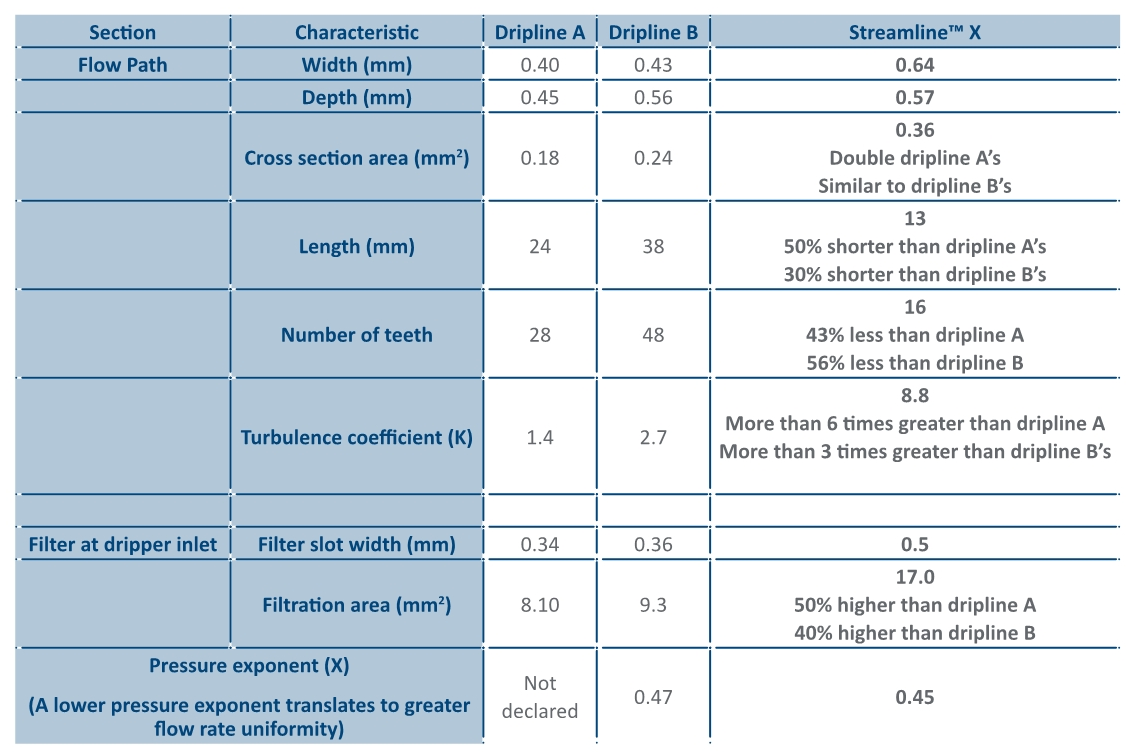

A variety of factors must be considered in dripper and dripline selection. The designer and/or farmer must determine which attributes are necessary for the crop and circumstances. The purpose is to maintain a balance between dripper cost and performance.

Remember, equipment cost is a sliding scale determined by a host of factors. A comprehensive portfolio of drippers and driplines is available that cover a wide range of crops and applications.

Consider a dripline selection graph where the y axis is cost and the x axis is a composite of application, durability, clogging resistance and other factors considered in dripper comparison. Movement along the x axis will result in movement along the y axis, that is an increase or decrease in price.

One of the attributes to consider is wall thickness. The thicker the pipe wall, the more durable the pipe is, but the more plastic it requires and the more expensive it will be. A thinner wall thickness will make the dripline much cheaper but will potentially open it up to a higher occurrence of dripline damage.

One aspect of a dripper’s specification is whether it is to be used in heavy, medium, or thin wall pipe. A big, advanced dripper meant to last a long time, will therefore go into a heavy wall dripline with suitable durability. At the other end of the spectrum, a small dripper which is at greater risk of potentially getting clogged and is only purposed for a single season, will be welded into a thin wall dripline.

It all boils down to what your crop needs. The experts would, for example, not recommend the same equipment for irrigation with hard, murky water for a single season, as for irrigation with the same water where the equipment needs to last many seasons. Similarly, the same equipment will not be used for irrigation with much better water quality.

Thin wall driplines

Thin wall driplines are defined as driplines with a wall thickness of 0.4 mm or less. These driplines are specifically designed to be used for one to three seasons on vegetables and certain field cash crops. It is also perfectly suited for temporary installation for strip wetting for germination.

If the attributes of advanced heavy wall driplines aimed at multi-seasonal use are more than your crop needs and your circumstances allow, these driplines become a waste of money and labour - something that cannot be afforded in modern farming, where efficiency is crucial to survival. Thin wall driplines can lead to significant cost savings when some attributes are no longer crucial.

Thin wall driplines are also the perfect solution in circumstances where a farmer may not have the capital outlay for the intended and preferred heavier wall dripline. A lower cost thinner wall can be used initially and upgraded to a heavy wall later once the crop brings in sufficient income.

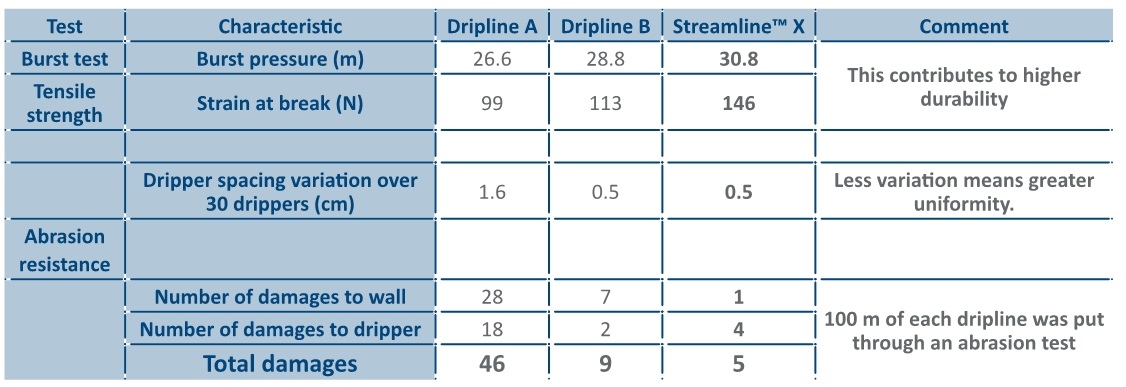

Regular users of thin wall driplines would however know that in-field dripline damage becomes a significant challenge when moving towards thinner wall driplines. Farmers do not have the time to treat driplines with kid gloves. In the field, you need irrigation equipment that does the job and survives the often tough conditions.

The toughest thin wall dripline ever made

Understanding this challenge, Netafim set out to create an extremely robust thin wall dripline that would still uphold the high level of efficiency of Netafim products. The aim was to create a durable dripline and to reduce the damage that occurs when driplines are installed or retrieved. Enter Streamline™ X.

The original Streamline™ X idea was drawn on a napkin. It was a simple idea. Just like cars have bumpers that protect their chassis from being damaged, this new dripline would be shielded by external and internal ribs that would act as a barrier between the ground and the pipe and protect the dripline from installation-related cuts and tears. The product was developed and tested and in 2019 the toughest dripline ever made was introduced into the market.

Share your thoughts

Comments

We'd love to hear your thoughts! To enter a comment, type your name and email address.