Low Flow Drip Irrigation - a journey to efficiency

“In my 35-year career in orchard irrigation, I have witnessed many changes, technological advances, and knowledge leaps. Of all of these, I believe the concept of low-flow drip irrigation has had the most significant impact. Yes, success in the orchard is the outcome of many factors, but efficient low-flow irrigation and fertigation has been especially significant,” says Johann du Preez, manager of Subtropicals at Citrogold.

Finding Optimal Irrigation

Du Preez notes that limiting water allocations partly prompted lower irrigation application rates. “For instance, a farmer might have 1 500 hectares but water allocation for only 450. The question became: How can I use water more efficiently to irrigate more land?”

Sharing the journey to low-flow drip irrigation at Bavaria Fruit Estates near Hoedspruit in Limpopo, Du Preez starts in the 1990s when there was a movement from seasonal to permanent crops, and many of their mango and citrus orchards were developed. “Drip irrigation was not yet widely implemented in South Africa, and the industry didn’t yet fully understand its management - an understanding that continues to evolve. Furthermore, many of the technologies, such as filtration and control solutions, weren’t quite where it needed to be for optimal open-field or orchard drip irrigation.”

In 1996, Du Preez and other South African irrigation experts attended a Mango symposium in Israel. “We initially developed the farm for micro-sprinkler irrigation, but with future expansion in mind I had to look at how we can use water and other resources more efficiently.

Based on what I saw at the symposium and beyond, I knew that we had to work towards increased use of drip irrigation and lower flow rates.

In 1997, we officially switched to drip irrigation. We installed 2 ℓ/h drippers, usually four per tree with varying spacing. Our system evolved through trials and research, and we eventually transitioned to low-flow drip irrigation around 2014.”

Data, scheduling and digging

For optimal water-use efficiency, Du Preez emphasises precise scheduling and knowing how much water to deliver when. “We used tensiometers and neutron probes to track soil moisture trends and adjust scheduling accordingly. We targeted optimal irrigation, but also prioritised a practical approach to data collection. We didn’t want data overload that could complicate decision-making. Instead, we focused on identifying soil moisture trends. We irrigated daily and measured weekly, which helped us adjust scheduling for the following week if the soil was too wet or dry. As agricultural technology advances, we can gather more data and manage irrigation systems more effectively. But we must remember that data is useless unless interpreted and acted upon.”

“Based on what we saw in the orchards, we started thinking in terms of three types of movements of water in soil: gravitational, capillary and what we called overflow. Overflow occurs when water delivery exceeds soil infiltration, causing surface wetness instead of deep saturation. “Often when large, wetted areas are visible when working with clay soils, it does not mean that you have a nice and broad wetted bulb, but rather that overflow occurred.”

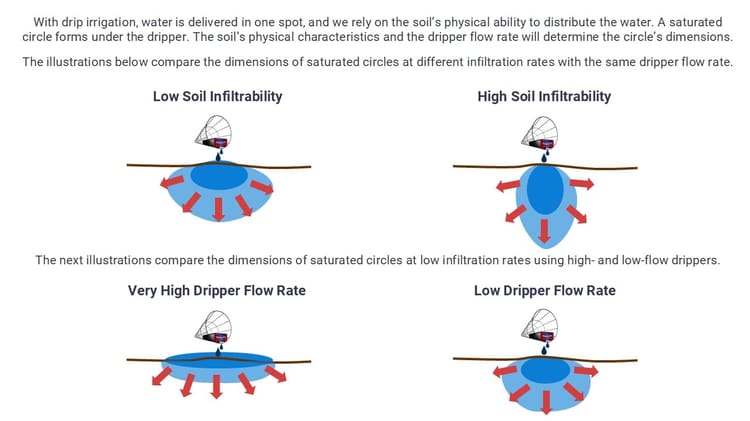

It is all about understanding the way water moves in soil, says Du Preez. “There are general concepts to understand, but more importantly you must know how water moves in the specific type of soil in your orchard. We know that water moves through soil as it is pulled down by gravity and distributed horizontally by capillary action. A wetted bulb or saturated circle form under the dripper, but the soil’s physical characteristics and the delivery rate of the dripper will determine the dimensions of this circle.”

“The more we investigated, the more we realised that we must use lower delivery rates to better balance the horizontal and vertical distribution of water.” Du Preez explains that the general rule of thumb is that a higher delivery rate and sandier soil will result in a deeper and narrower wetted bulb, while soil with higher clay content will result in a shallower and broader wetted bulb.

“We however quickly realised that that is not the full picture. “With high delivery rates the gravitational force is dominant, however when water is delivered at very low rates, especially in sandy soils, the capillary force becomes much stronger than is traditionally thought and the horizontal movement becomes more dominant. We see increased horizontal movement of water in our soils when a delivery rate below 1 ℓ/h is used. According to Du Preez, digging profile pits and seeing this type of water movement in soil changed the way they thought about irrigation technology and scheduling.

Theory and practice

Practicality often trumps theory, Du Preez notes, explaining that they adapted reigning theories to suit what Bavaria’s setup at that time made possible. We applied principles from irrigation experts such as Professor Rafael Martinez but had to adapt it to make it practically feasible.

“Around 2003, we set up a small project with a permanent neutron probe station to see exactly how water moves in our soil. This was beyond our regular profile pit inspections. We learned that optimal water delivery in our soils with 2 ℓ/h drippers meant that we had to practice pulse irrigation with a pause of 23 to 35 minutes between pulses. With the system we had and technology available to us at that stage, this was simply not possible. Our system design had cluster valves and a central mainline feeding four orchards each side of the mainline. Our ability to apply radio control was also limited and we had to turn our approach intro practice with an irrigation attendant on a bicycle. It was about finding optimal irrigation and efficiency within our limitations at that time. This meant actioning pulses of around 43 minutes with an hour between pulses.”

Interestingly, says du Preez, lessons learned along the way were often quite logical. Once the problem or shortcoming is picked up, it can be easily solved with a practical, logical solution, adapting as they go. This includes actions such as moving double line driplines closer and further apart according to proven trends, adapting irrigation hours, and more.

The benefits

Beyond the obvious benefits of low-flow drip irrigation, which include reduced water, fertiliser, and energy use, it offers additional tools that are especially valuable in low rainfall areas. These include deficit irrigation or the ability to increase the application of relevant nutrients in certain phenological stages. These tools typically give the producer more control over fruit size, colour and more.

Du Preez attests that fertigation through low-flow drippers tremendously reduces fertilizer use, not only compared to other irrigation methods but also to higher flow drip systems. “Fertilizers are delivered more efficiently because the nutrient-rich water is not delivered beyond the root zone, reducing the risk of leaching. According to Du Preez, there are orchards where they used up to 30% less nitrogen, yet foliar analyses show higher nitrogen levels compared to trees in orchards where more fertilizer is applied less efficiently.

There are few instances where a record yield is the result of only one action or technology. It is the culmination of many management actions and seasonal factors that interact in a holistic manner. “Therefore, saying that low-flow drip irrigation leads to higher yield can always be debated, but the massive savings in terms of resources can no longer be questioned. We use up to 50% less water in low-flow orchards compared to micro-sprinkler orchards, and up to 25% less compared to high-flow drip orchards. Fertilizer savings with low-flow drip fertigation are as high as 30% for some elements compared to high-flow drip irrigation systems.”

“The key question isn’t whether low-flow drip irrigation increases yields, but whether it maintains or improves yield quality while using fewer resources. In my experience, yields remain stable and many of our low-flow orchards even outperform others. The ability to sustain production with significantly lower resource use is a major advantage - any yield increase is a bonus.”

Challenging misconceptions

Despite proven successes, the most persistent misconception about drip irrigation - especially low-flow drip irrigation - is that it cannot deliver enough water to crops. This has been disproven time and again. With the right setup and management, drip irrigation systems can easily meet water demand efficiently and consistently.

Du Preez provides a practical perspective: “Most micro-sprinkler irrigation systems are designed to irrigate every three days for cost efficiency. But how much control does that give you over water delivery? If you wanted to irrigate daily, the system would have to be oversized and prohibitively expensive.”

“If the argument is that you must be able to deliver at least 150 ℓ/day every three days, let’s unpack that: Take 0.7 ℓ/h drippers spaced at one meter with double driplines, with which you are able to irrigate 24 hours per day due to the reduced system capacity requirements. With eight drippers per tree, spaced four meters apart, you can deliver 5.6 ℓ/h per tree - amounting to 120 ℓ/tree/ day. That is more than enough, in fact way too much. The fact is that you can deliver enough water with drip irrigation, it is just delivered in a much more efficient way.”

Some argue that micro-sprinklers offer better humidity control, but Du Preez clarifies: “Humidity is crucial, but it’s a misconception to believe micro-sprinklers provide better control. For efficient humidity control, you need an overhead system. Ground-level micro-sprinklers, delivering 50 ℓ/h, can’t manage canopy humidity.”

Another common argument is that drip systems can’t keep up with peak water demand during midday when transpiration is highest. “That is why you start irrigation earlier in the day and efficiently fill up the soil reserves. You are building a buffer. In addition, what are the chances that you will be able to irrigate every tree during peak hour with an economically designed micro-sprinkler system?”

“In my experience you may deliver a little bit less water per day irrigation cycle, but if it is managed correctly, you can maintain the soil water profile with drip irrigation. It is not about letting the profile run empty, and then filling it up as you would do with other irrigation systems, it is about maintaining the necessary moisture levels. I like to compare it to intravenous nutrition, giving little by little as you need it.

Du Preez acknowledges that low-flow drip irrigation requires more precision. ‘It’s true, you need more advanced filtration, more accurate backflush management, and precise control over fertilizer dosing, but you can irrigate 100 hectares with one person managing the system, you have a host of crop management tools at your disposal and your resource use is much lower.

“The big condition to success is that drip irrigation must be managed correctly. I often meet farmers who wants to hear nothing about drip irrigation, because they gave it a try and failed. When you start talking to these farmers about the details of the failed drip irrigation project, it always leads back to them being poorly advised and the system managed incorrectly. You need to understand how the water is delivered by the system and accordingly how the water delivered moves in your soil. Then, you can manage the system efficiently, optimally and with great success.”

Optimal irrigation

Du Preez stresses that optimal irrigation demands understanding both the crop and local climatic conditions. “Efficient irrigation provides the tools for precise crop management. It’s about timely, need-based water delivery and integrating all influencing factors to manage the crop based on phenological stages for optimal production. A holistic approach is necessary where all data and impacting factors are integrated.

“Low-flow drip irrigation allows you to take the necessary action exactly when it is necessary, according to your knowledge of the crop and conditions. With low-flow drip irrigation, we can manage a plant based on phenological stages for optimal production. The more efficiency your irrigation system offers, the more tools you have at your disposal.

But, says Du Preez, as technology advances, we must remember that you can achieve very efficient irrigation even with older and less efficient irrigation systems, if you use the system optimally, understand the system well and truly understand what the crop requires. “It is about doing the basics right. There is a lot to understand and many ways to continuously improve and innovate, but there are key basics to understand, and these must always remain in place. It all depends on the conditions, the resources, the skillset of the team on the farm and the production goals.” He emphasises the importance of doing the necessary research and planning before the irrigation system is designed and installed. “There are many important decisions to be made.”

The word ‘understand’ has been used in this article multiple times. According to Du Preez it is not about understanding drip irrigation, but understanding how water moves in soil. “This may be difficult to explain or learn theoretically, but often easy to illustrate. If we can dig profile pits after active irrigation or do water distribution test before system planning, all the forces that affect water movement changes from theoretical concepts to something you have seen in action. A lot happens in an orchard or field, the more you understand the effect water can have as tool for optimal production, the better you can use it.

Share your thoughts

Comments

We'd love to hear your thoughts! To enter a comment, type your name and email address.