Key concepts in informed filter selection

The filtration system is a key part of any successful irrigation system. With so many factors affecting the workings of a filter and how it should be implemented, filter solutions will never be ‘one size fits all’ or ‘plug and play’. Each irrigation system and the circumstances under which it operates will require a different filter setup, as well as various operation and maintenance activities.

Filters have an important function

System capacity

Filter types

There are three main types of filtration systems. These are media filters (sand or gravel), disc filters and screen filters. Each type has different features, advantages and shortcomings that make them suitable for various irrigation scenarios. Let’s consider how each filter works to evaluate the value of each of these filter types.

Filter selection

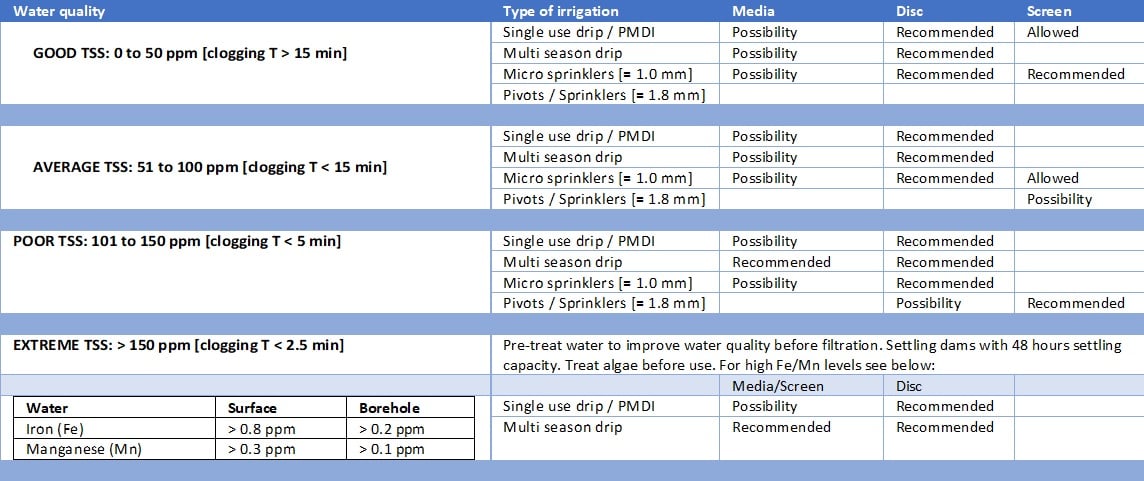

Although it is very simplified and each choice will be determined by the unique circumstances of an irrigation project, the table below indicates filtration type selection based on physical water quality and the type of irrigation used. Filtration selection is not straightforward, as it involves a long list of variables.

Quality and knowledge

Share your thoughts

Comments

We'd love to hear your thoughts! To enter a comment, type your name and email address.