Irrigation Automation in Action

The previous Netafim Knowledge article on irrigation automation deliberated how digital farming technologies unlock the full potential of precision irrigation. “It is about the ability to timeously and accurately execute precision irrigation strategies based on precise data. Even with a lot of effort and time, and the right precision emitter at the plant, 100% precise execution of strategic precision irrigation and fertigation tasks will not be possible without automation,” said Nickie Theron, Netafim Southern & East Africa’s Product Manager specialising in Digital Farming.

Click here to read the article.

In this article, we speak to Netafim digital farming experts and two automation users to continue the conversation on this ever-evolving industry and the impact of irrigation automation on the farm.

Overcoming Challenges

The natural starting point of any conversation about irrigation automation is often the challenges that negatively impact the adoption of these technologies. According to Jared Gouws, Digital Farming Technician at Netafim Southern & East Africa, there are clear-cut reasons why these challenges should not discourage farmers from adopting irrigation automation technologies. “The main challenge is often the high initial cost. However, this cost will be offset by the resulting long-term savings in resources. Suppliers can also address this by offering modular solutions that directly meet farmer’s needs.” Gouws lists the reasons why challenges such as high cost and the often overwhelming unfamiliarity of these technologies should not be a discouraging factor:

- Long-term savings: Reduces water waste and labour costs, often paying off the initial investment.

- Improved crop health: Precise watering and fertigation lead to healthier plants and better yields.

- Sustainability: The precision made possible by automation helps conserve water and other resources.

- Continuous Improvement: Systems are improving continuously, becoming more affordable and user-friendly.

- Competitive Advantage: Increases productivity and resilience.

Theron identifies two main drivers of the implementation of irrigation automation. “The first is the need to unlock precision fertigation and the capabilities of EC/pH control to push crops to their full potential and use resources efficiently. The second driver is often scale. When a farm grows to a certain size with many valves, it becomes simply impossible to keep up with manually opening and closing these valves. It also becomes near impossible to monitor, keep records and do any other necessary precision tasks.”

We checked in at two farms where irrigation automation is implemented, at two very different scales. The producers speak about the different impacts of non-automated and automated irrigation, and the many benefits experienced when adopting irrigation automation.

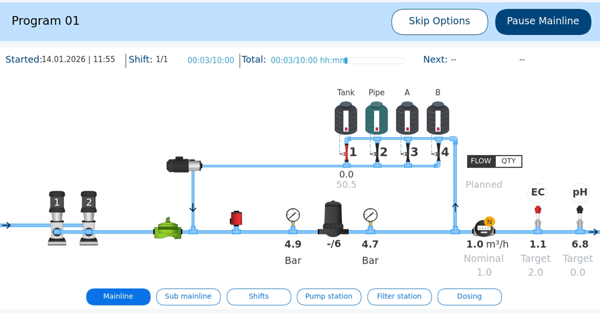

Automation at Mosplaas

Mosplaas is a 400-hectare production unit in the Karsten Group. The farm, located near Kakamas, produces grapes and citrus under irrigation and fertigation run from two head control rooms. In the first head control room, that serves around 250 hectares with nine mainlines, eight Netafim NMC controllers were recently upgraded to two Netafim GrowSphere™ MAX controllers. These two units, enabled by RadioNet communication with the field, offer the platform to fully manage the area under irrigation. The second head control room, serving around 120 hectares with five mainlines, saw five NMC controllers converted to two GrowSphere™ MAX controllers, leaving space for expansion in the future.

The team at Mosplaas places massive value on irrigation automation and has been harnessing the value of automation for many years. “I always illustrate the importance of irrigation automation with an example of one of our older blocks, that have not yet been automated,” says Gert Loubser, Horticulturist at the Karsten Group. “It is a six-hectare block, with eight valves that must be opened to irrigate the entire block at once. The valves are far apart and takes half an hour to open or close manually. Yes, the entire block is eventually irrigated, but there is no pressure management, and you do not know how much water every tree receives. In short, there is no precision.” Loubser continues that investing in the efficient automation of this block is a no brainer, as is the case for every block on the farm. He further lists benefits such as reduced labour requirements, accurate monitoring, efficient fault finding and precise pressure management ensuring precise water and nutrient delivery.

“One of the greatest benefits of irrigation automation is that actions can be activated exactly when necessary. This means that you can adapt your irrigation to actual conditions in real time and you don’t have to be dependent on a preset plan that is based on assumptions. You can irrigate at any moment from anywhere. I do not believe you can give each tree exactly what it needs when it needs it, if you do not have the flexibility to irrigate after hours when teams are not necessarily on the farm.” He concludes that irrigation without automation is inefficient and unreliable in their context.

Monitoring and Communication

According to Loubser the monitoring capabilities unlocked by irrigation automation adds a massive layer of benefits. “Not only is monitoring crucial to being precise, but there are also a lot of monitoring demands for export compliance. I can pull a treasure trove of data from my GrowSphere™ MAX controllers.”

This data is stored on the cloud for easy accessibility and offers visual representations to bring the information to your fingertips. “In modern farming, data overload is a true risk, but the controller accumulates data logically and it is well presented, which gives it added value.”

Data collected includes:

- Exactly how much water was irrigated per valve per irrigation event, or over time

- All irrigation events

- Any data from sensors in the field

- How much fertilizer was dosed

- Much more.

“Furthermore, faults in the system are easily identified through anomalies in the data, whether the system alerts you of these anomalies or you identify them in the accumulated data. This means that problems can be sorted out quickly and efficiently, limiting the damage.”

Communication, he says, is a keyword in irrigation automation. “None of the many benefits I have mentioned will be possible if there is no communication between the head control room and the block. This is also the area where the most challenges occur given distances that must be covered, physical challenges in the orchards and more. “When selecting equipment, it is important to focus beyond controllers and irrigation equipment and put sufficient emphasis on communication technologies to ensure that everything can be integrated.”

Share your thoughts

Comments

We'd love to hear your thoughts! To enter a comment, type your name and email address.