Hit the target with dripline selection

The agriculture industry’s aim is firmly locked in on precision, efficiency, and overall sustainability. This is driven by the many factors we know so well, such as rising input costs, narrowing margins, increasing food demand and more. In this context, farmers need the right tools that must be applied optimally in order to hit the target successfully.

If you try to hit a nail with the handle of a hammer, or a screwdriver for that matter, the nail might go in. Will you however truly hit the nail on the head? If you irrigate with the wrong type of irrigation system for the circumstances, the wrong dripline for the irrigation task at hand, or use the wrong scheduling approach, can you truly harvest optimal yield, use resources with perfect efficiency and manage your crop effectively to overcome challenges? Can we hit a bull’s eye without the right tool for every job?

In the drive to promote the precise application of water and nutrients, drip irrigation is advocated as the optimal solution. Drip irrigation offers elevated levels of efficiency. Increased yield size and quality as well as resource savings are pledged as the main benefits of this irrigation method. All of this is however dependent on suitable water availability, the selection of suitable driplines and other equipment, correct installation, smart scheduling, and faithful maintenance.

Many important selection and planning decisions must be made to ensure the success of drip irrigation in the field. Of course, this only comes after drip irrigation was selected as the most suitable irrigation method, based on a holistic view of the farming conditions and production goals. Dexter Neethling, Product Manager at Netafim South Africa, lists the following as some of the important factors that should be considered:

- Climate

- Crop and production season

- Soil type, composition, and behaviour

- Water quality and availability

- Topography

- Electricity availability

- Risk of diseases and pests

- Fertiliser requirements

- Capital and running costs of the system

- The farmer’s knowledge and skills

- Installation, operation, and maintenance limitations

- Possibility of theft

Dripline Decisions

Neethling explains that selecting the correct dripline requires you to check three boxes:

- Selecting the dripline with the most suitable specifications and features

- Selecting a high-quality dripline

- Balancing dripline performance and dripline cost to ensure optimal ROI

To achieve this, important selection decisions must be made in these categories:

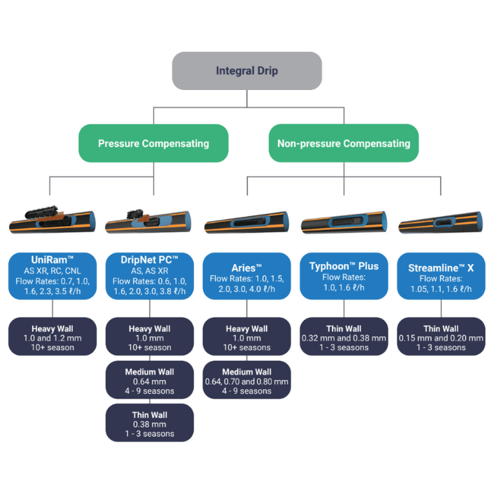

- Dripper type, features and specifications

- Dripline wall thickness

- Dripper flow rate

- Dripper spacing

- Dripline supplier

Dripper Deliberation

Since the start of drip irrigation innovation in 1965, dripper technology has come a long way - widening the possibilities of its application, enabling victory over challenges in the field, and increasing the precision with which water and nutrients can be applied.

According to Neethling an important part of dripline selection is considering the many innovative dripper features, and determining which attributes are required for the task at hand. “Of course, it is important to only get the bells and whistles that are truly required to overcome the unique challenges of the production unit, keeping cost-efficiency in mind.”

Dripper Features:

- Pressure compensation

- Anti-siphon

- Flap outlet

- Root intrusion inhibitors

- Non-drainage

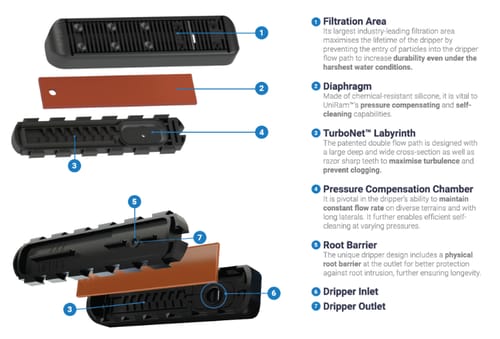

Beyond dripper features aimed at overcoming specific challenges, Neethling reminds us that every dripper has certain technical specifications that will determine both its suitability to the application and how well it can do its job. “These data points contain crucial information for the irrigation designer when doing the math during the design of the drip irrigation system.”

Technical Data:

- Size of the effective filtration area

- Working pressure range

- Filtration requirements

- Turbulence coefficient

- Pressure exponent

- Head loss

- Dripper size (longevity)

- Wall thickness suitability

To make optimal decisions around a dripper’s technical specifications and features, Neethling lists the following as impacting factors:

- Installation: Surface or sub-surface

- Required dripper longevity (seasonal vs permanent drip)

- Topography

- ROI calculations (Crop value and other impacting factors)

- Possible production challenges

Share your thoughts

Comments

We'd love to hear your thoughts! To enter a comment, type your name and email address.