Efficiency sugar’s only defence against challenging headlines

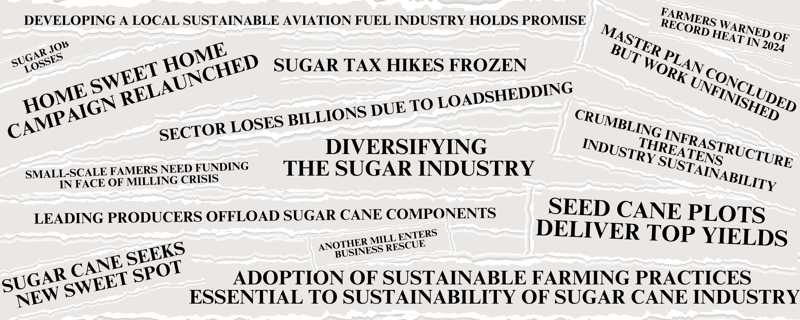

Having browsed publications in the sugar and wider agricultural industry, these are some of the many headlines that catch the eye. The industry has been under pressure for many years, faced by pricing issues, climate risk, increasing input costs, teetering profitability and more. In fact, according to the Bureau for Food and Agricultural Policy, the sugar industry has been in steady decline over the last 20 years with substantially higher production costs, industry uncertainty and increased competition in the markets dragging it down.

A lot can be said about the importance of the industry; opportunities in the industry; the politics surrounding the many factors impacting production; efforts towards enabling growth and recovery; who should do what, and more. But let’s focus on what happens in the field.

Let’s focus on producing yields of optimal size and quality as efficiently as possible. Fact is – producers have no choice but to farm their sugar cane hectares as efficiently as possible.

SELECTING SUCCESS

A successful farming enterprise is one of the most complex economic activities as success depends on such a wide-ranging list of factors that any attempt to compile a complete list would be futile.

Success depends on everything from soil preparation to harvesting practices. It depends on many factors beyond producers' control, but it also depends on important decisions producers and the experts they consult, make. When these decisions are being made, a vast list of variable factors must be considered.

Let’s chat about the decisions specific to irrigation. First on the list will be selecting a method of irrigation. Having the right tools for the job is a crucial element of efficient irrigation.

An informed decision must be made, comparing all suitable types of irrigation to find the best fit for your circumstances, ensuring water- and nutrient-use efficiency as well as optimal production. A properly designed and planned irrigation system that is managed correctly, will accommodate all variables, and will therefore ensure total control of water and nutrition levels. Consider all the advantages and disadvantages of a system and be sure to base your decision on the circumstances of the production unit, given all the variables.

Some of the variables to be considered are:

- Climate

- Soil type (physical and chemical attributes).

- Water composition and availability.

- Topography

- Availability of electricity.

- Diseases and pests.

In addition, the final decision regarding the type of irrigation system will be determined by the experience and knowledge of the farmer or irrigation manager, as well as the production goals. A second list of variables must be considered:

- Capital and running costs of the system.

- The farmer’s knowledge of and familiarity with the system.

- The management requirements, ease of maintenance and the team’s ability to adhere to the guidelines.

- The reliability of the system considering the circumstances.

- The necessary capacity in terms of nutrition management and scheduling.

- The occurrence of wind, weeds etc.

- Installation requirements – especially in terms of labour and equipment.

- Possibility of theft.

A farmer’s decision to adopt a certain technology or practice is driven by a heightened need or a specific challenge. Producers face many agronomic and environmental challenges, such as water scarcity and sandy soil, in addition to many industry-level challenges as mentioned above. The irrigation industry, in cooperation with other input suppliers, must enable farmers with the tools they need to overcome these challenges. Leading industry role-players, such as Netafim, have the important task to identify these challenges and help farmers by offering ever-improving solutions that satisfy the need for greater yield; use fewer resources and put more money in the farmer’s pocket.

EFFICIENCY IN EVERY DROP

Drip irrigation has been a proven sugar cane irrigation practice for several decades. Given the harvesting practices employed in sugar cane production, subsurface drip irrigation has become the preferred method.

Burying driplines make it possible for a farmer to implement drip irrigation to support the crop in all growth stages, without the lines being damaged at harvesting. It also enables drip irrigation installations to be used for multiple seasons.

In sugar cane production, experience has shown that proper soil preparation before planting creates an ideal soil condition for healthy root development in the top 30 – 50 cm as well as effective water distribution.

This leads to larger and healthier root zones and consistently higher crop production. The correct amounts of water and nutrients must be delivered to the root zone at the right time so that the crop is never under stress. Well-planned and informed scheduling is required to prevent over- or under-irrigation.

Utilising drip irrigation, in combination with optimal planning and preparation, as well as precise irrigation management, will contribute to a higher return on investment and increased sustainability.

The key reasons for this are:

- Scheduling and management can be adapted to reduce losses caused by load shedding.

- The system can be implemented in different ways to answer to the specific crop and system

- needs of each stage of production. Be it long irrigation after planting for germination, pre-dry off

- treatments to prevent any root intrusion of drippers, or peak season irrigation.

- Subsurface drip can be left in the field when the cane is burned.

- Easy post-harvest maintenance can be done as the effect of the water, or the lack thereof can be

- seen easily.

- Plant protection, mill effluent or bio-stimulants can be delivered directly to the root zone.

- Odd-shaped or steeply sloping lands can be used optimally.

- System installation and operation requirements lead to reduced labour costs.

- Buried driplines and other system characteristics carry a lower risk of theft.

- Improved irrigation and better overall crop management leads to:

- An overall higher and more stable yield in any climate.

- Better plant quality, with a higher sucrose content.

- More ratoons from each planting cycle.

- Considerably lower water-use and more efficient fertiliser application

All of these factors boil down to a single truth: drip irrigation can help sugar cane farmers grow more cane with fewer inputs, effectively helping to make the industry as a whole more sustainable. Drip irrigation allows producers to take full control of water and nutrient delivery. There are so many factors that producers cannot control. So why not seize full control of those that can be controlled? The result: consistent and profitable production in the field – year after year.

DRIP DECISIONS

Looking at this list of advantages and given its high level of efficiency, drip irrigation is often seen as a near-magical irrigation solution. The installation of drip irrigation comes with expectations of skyrocketing yields with minimal water use. These are, of course, not empty expectations, but are dependent on suitable water availability, the selection of the drip irrigation system best suited for your circumstances, correct installation, smart scheduling, and faithful maintenance.

Decisions regarding dripper type, wall thickness, flow rate, spacing and other system requirements, must be based on detailed information. Each irrigation system will differ depending on the environmental conditions and system requirements at hand. Including the necessary experts in this process is crucial to success.

Important selection parameters and drip features must be considered. Although final selection depends on many factors. Netafim has recommendations for each of these parameters:

Wall thickness: Based on installation and replanting practices, a medium wall dripper generally offers the best return on investment.

Diameter: 16 mm, and 22 mm for longer haulage runs.

Flow rate: The availability of lower flow rates enables irrigation of a larger area at once.

Dripper spacing: Shorter spacing between drippers will result in higher costs but will be more effective. Decisions regarding dripper spacing must be based on soil texture and water holding capacity.

Pressure compensation (PC versus non-PC): PC drip costs more per meter but will lead to more uniform delivery. This is a requirement especially when fields are sloped, and longer laterals are used.

AS (anti-siphon): (Flap-over drip outlet or built-in anti-siphon technology) This prevents dirt suction and is especially important in subsurface installations.

INSTALLATION AND MAINTENANCE

The precise application of water and nutrients through drip irrigation has many benefits, but these benefits- are lost if systems are not installed, operated, and maintained with the necessary expertise. In case of drip irrigation on sugar cane, correct installation is crucial to ensure that the system can efficiently yield the many promised benefits and prevent problems down the line. Furthermore, suboptimal operation and maintenance will jeopardise the efficiency and longevity of an irrigation system. It has become clear that the adoption of drip as an irrigation technology and the results achieved by the implementation of this technology are often held back by suboptimal or inefficient implementation of systems. Most often, this is due to insufficient knowledge about the system and a lack of specialised expertise.

Optimal management and system maintenance is crucial for all types of irrigation systems. We must remember that regular preventative maintenance of the entire irrigation system can amount to significant cost savings as it prevents breakdowns and prolongs equipment longevity.

By checking all the boxes – selecting the correct system, doing proper planning and preparation, ensuring proper installation, management and maintenance, drip irrigation and the efficiency it brings can be the industry’s shield against the many challenges it faces.

Share your thoughts

Comments

We'd love to hear your thoughts! To enter a comment, type your name and email address.