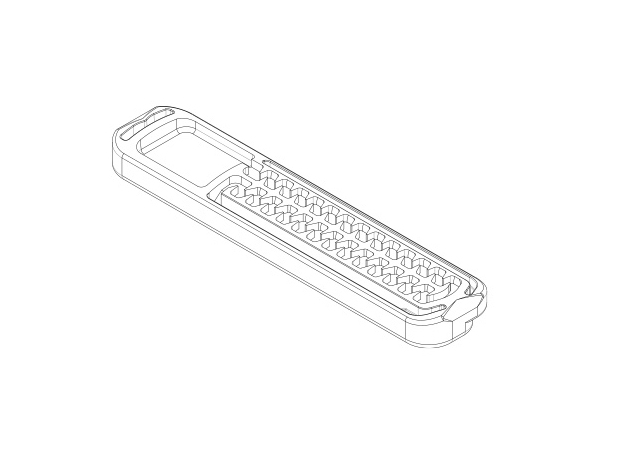

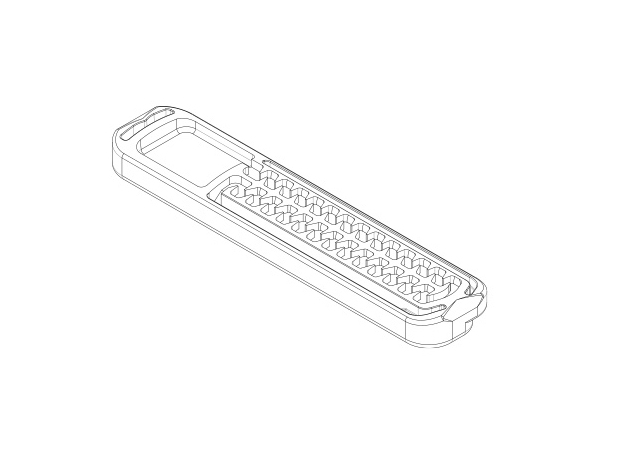

Dripperlines and Drippers

The most critical part of your precision irrigation system. Learn about the innovation behind the world’s most clog-resistant drippers and dripperlines that have been trusted by millions of farmers for more than 50 years.

Millions of farmers in more than 110 countries are producing higher and better-quality yields with precision irrigation. Get the tailormade solutions you need to make each season better than the last.

Driven by the specific needs of farmers around the world, our innovative products are designed to ensure increased accuracy, control and uniformity across the range.

The most critical part of your precision irrigation system. Learn about the innovation behind the world’s most clog-resistant drippers and dripperlines that have been trusted by millions of farmers for more than 50 years.

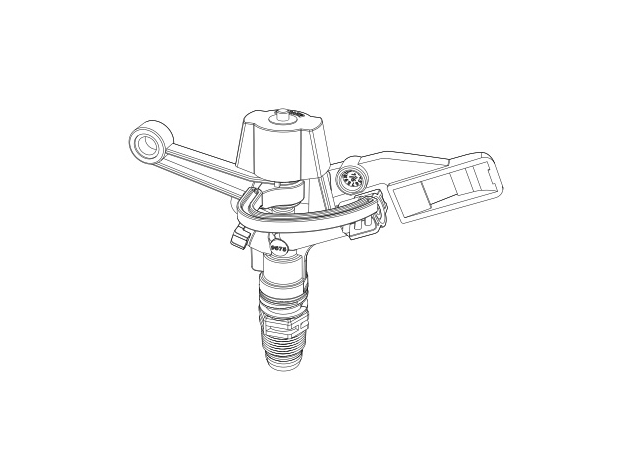

To produce uniformly better crops, you need a uniform distribution of water. Find out how to get more effective germination, healthy crop growth, frost mitigation, cooling or humidification for your crops.

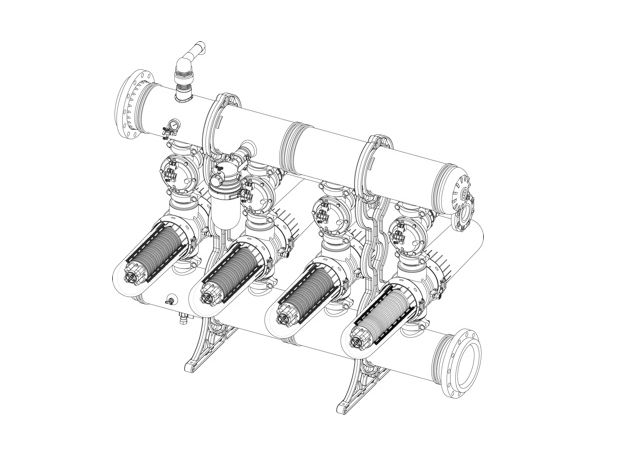

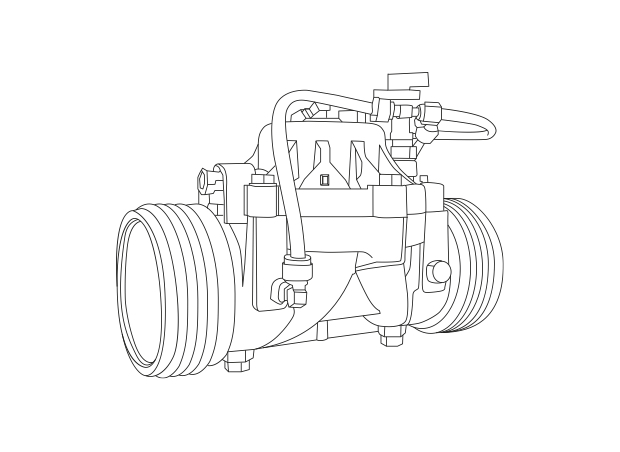

Protect your irrigation system from even the harshest water conditions. Learn about the innovations making disc, screen and sand media filters more durable, simple and reliable.

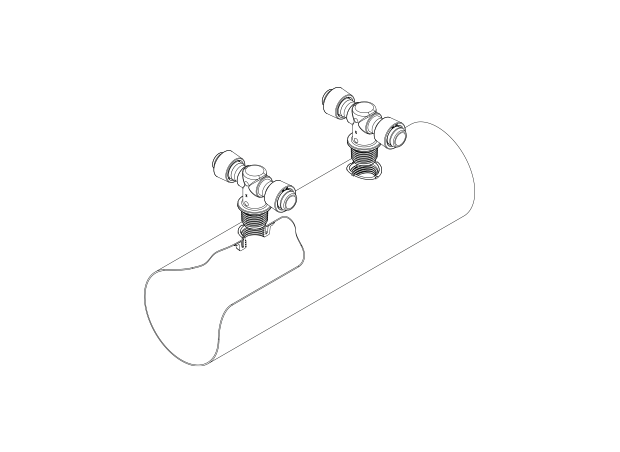

The gatekeepers of your precision irrigation system. Find out how the right valves make your life simpler by reliably controlling flow rates and pressure and allowing you to automate system operation.

The right pipes do more than move water. They’re lighter, tougher, easier to use and they connect more intelligently to the rest of your irrigation system.

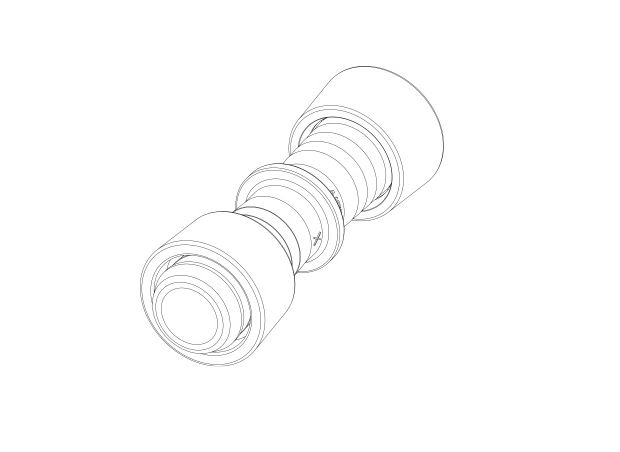

The most reliable connectors are the ones you trust to stay in place and last longer. They’re made from premium materials, are easy to install, and based on a design that keeps them in place, even under pressure.

Get in touch and we’ll talk you through everything you need to know.