Maize

Here’s how you increase grain yields while reducing costs and resource use.

In the past, if you wanted to grow more, you needed more fertiliser, labour or land. Precision irrigation is about reversing this age-old relationship between cost and output.

It’s about delivering the perfect amount of water and nutrients straight to the roots of each plant – not the soil. So you grow bigger, better yields every season – with fewer resources.

To maximise both your yields and your long-term success, our agronomists work with you, offering personalised support, guidance and best practices every step of the way. Whatever your challenges, they’ll provide you with the most accurate, up-to-date global intelligence on how to use precision irrigation to improve your yields and crop quality, based on over 50 years of experience.

Here’s how you increase grain yields while reducing costs and resource use.

Learn to increase your annual yields, maximise your sucrose content, and boost your water and fertiliser use efficiency.

Precision irrigation offers an increased avocado yield of up to 30% as well as super-fast ROI. Learn how.

Learn to control growth, boost grape quality, enhance your yield, and optimise your water-use efficiency.

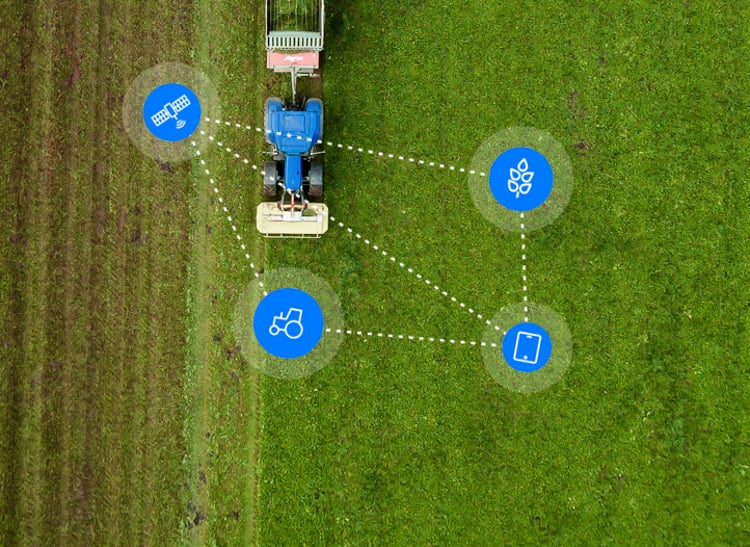

Monitor, analyse and optimise every stage of every plant’s lifecycle

Get more precise, automated control over every detail of your farm, and deeper insights into your crop health, soil conditions and yield performance – with support and guidance at every step. So it’s easier to run your farm and boost your profitability.

Learn More

Today, the best way to deliver bigger, better, more profitable yields is also the most sustainable agriculture. Find out how we work with partners to protect the environment, empower populations and enable global prosperity with precision irrigation.